MS Tuning

From LEAP

(New page: {{LSApp |name = LC Column Switching & Regeneration |image = M-001.png |type = '''SPECIAL''' |id = M-001 |description = LC Column Switching & Regene...) |

Current revision (22:39, 6 November 2009) (view source) |

||

| (8 intermediate revisions not shown.) | |||

| Line 1: | Line 1: | ||

{{LSApp | {{LSApp | ||

| - | |name = | + | |name = Mass Spec Tuning and column selection |

| - | |image = | + | |image = Tuning-PlumbDiag.png |

|type = '''SPECIAL''' | |type = '''SPECIAL''' | ||

| - | |id = | + | |id = Project Ref: H1108 |

| - | |description = | + | |description = MS tuning |

}} | }} | ||

| - | [[Image:LEAP Logo.png|frame|www.leaptec.com<br>www.leapwiki.com]] | + | [[Image:LEAP Logo.png|frame|[http://www.leaptec.com leaptec.com]<br />[http://www.leapwiki.com leapwiki.com]]] |

| + | |||

=== Overview === | === Overview === | ||

| - | This configuration allows | + | This configuration allows MS[http://www.leapwiki.com/mediawiki/index.php?title=Category:Mass_spectrometry] tuning and column selection. This is run directly from within '''Analyst® Software'''[https://products.appliedbiosystems.com/ab/en/US/adirect/ab?cmd=catNavigate2&catID=600927&tab=DetailInfo] from ''Applied Biosystems Inc® '' using a LEAP Cycle (requires ICC-CE software) [http://www.leaptec.com/products/lc-related-instruments-and-accessories/ctc-lc-pal-software/instrument-control-components-and-cycle-editor-181.php]. |

| - | + | This configuration requires a 6 port valve[http://www.leaptec.com/products/lc-related-instruments-and-accessories/ctc-lc-pal-injection-valves/6-port-2-position-valve-155.php] for sample loading of the MS tuning and a TrioVS valve[http://www.leaptec.com/products/lc-related-instruments-and-accessories/rotors-and-inlet-sleeves/pal-trio-vs--valve-system--80.php] for LEAP created analytical cycles. All valves must be controlled by the LEAP cycle. | |

''Please note: LEAP can not control the MS Selector valve as part of the cycle.'' | ''Please note: LEAP can not control the MS Selector valve as part of the cycle.'' | ||

| - | + | There are four LEAP created Analyst cycles. | |

| - | + | The first LEAP created cycle is known as a Tuning cycle. It takes samples and passes them directly to the Mass Spec through the stand-alone 6-port LC Valve. By directly, it is meant to emphasize that the sample does not pass through any column whatsoever during its passage to the Mass Spec. | |

| - | + | The second and third LEAP created cycle Analyst cycles inject the sample to the top valve of the TrioVS. The difference between the two cycles is that one passes the sample through column A (connected to ports 10 and 7 of the 2nd Valve of the TrioVS) on its way to the Mass Spec, while the other cycle passes the sample through column B (connected to ports 2 and 5 of the 2nd Valve of the TrioVS). | |

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| + | The final LEAP created cycle Analyst cycle is used for a single-column application. In this scenario, the second valve of the TrioVS is bypassed altogether. The column will be included in the plumbing lines connecting the 6-port valve of the TrioVS to the selector valve of the TrioVS. | ||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | [[Image: | + | [[Image:Tuning-PlumbDiag.png|center]] |

| + | |||

| Line 80: | Line 35: | ||

* Dual Channel Parallel Injection (M-005) using LEAP Shell software [http://www.leapwiki.com/mediawiki/index.php?title=M-005_Dual_Channel_Parallel_Injection_-_LEAP_Shell_%22(M-Fab)%22] | * Dual Channel Parallel Injection (M-005) using LEAP Shell software [http://www.leapwiki.com/mediawiki/index.php?title=M-005_Dual_Channel_Parallel_Injection_-_LEAP_Shell_%22(M-Fab)%22] | ||

* LEAP Shell Software and application for custom injections and scheduling [http://www.leaptec.com/software/leap-shell-3.php] | * LEAP Shell Software and application for custom injections and scheduling [http://www.leaptec.com/software/leap-shell-3.php] | ||

| + | |||

---- | ---- | ||

| - | [[Image:LEAP Logo.png|frame|www.leaptec.com<br>www.leapwiki.com]] | + | [[Image:LEAP Logo.png|frame|[http://www.leaptec.com leaptec.com]<br />[http://www.leapwiki.com leapwiki.com]]] |

| - | + | This workstation application is based on the CTC PAL X, Y, Z syringe only autosampler robot from LEAP Technologies. This extremely flexible, precise, and adaptable robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your LC or GC requirements. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible automation. | |

| - | + | === Contact LEAP === | |

| - | + | [[image:Contact_Info.png|40px]] [http://www.leaptec.com/contact-us.php Contact the LEAP office] | |

| - | + | ||

| - | + | ||

Current revision

| Mass Spec Tuning and column selection |

| Application Type | |

| SPECIAL | |

| Application ID | |

| Project Ref: H1108 | |

| Description | |

| MS tuning |

Overview

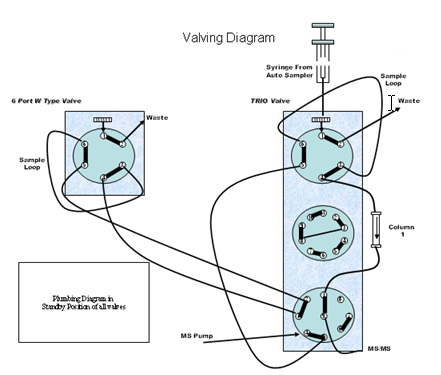

This configuration allows MS[1] tuning and column selection. This is run directly from within Analyst® Software[2] from Applied Biosystems Inc® using a LEAP Cycle (requires ICC-CE software) [3].

This configuration requires a 6 port valve[4] for sample loading of the MS tuning and a TrioVS valve[5] for LEAP created analytical cycles. All valves must be controlled by the LEAP cycle.

Please note: LEAP can not control the MS Selector valve as part of the cycle.

There are four LEAP created Analyst cycles.

The first LEAP created cycle is known as a Tuning cycle. It takes samples and passes them directly to the Mass Spec through the stand-alone 6-port LC Valve. By directly, it is meant to emphasize that the sample does not pass through any column whatsoever during its passage to the Mass Spec.

The second and third LEAP created cycle Analyst cycles inject the sample to the top valve of the TrioVS. The difference between the two cycles is that one passes the sample through column A (connected to ports 10 and 7 of the 2nd Valve of the TrioVS) on its way to the Mass Spec, while the other cycle passes the sample through column B (connected to ports 2 and 5 of the 2nd Valve of the TrioVS).

The final LEAP created cycle Analyst cycle is used for a single-column application. In this scenario, the second valve of the TrioVS is bypassed altogether. The column will be included in the plumbing lines connecting the 6-port valve of the TrioVS to the selector valve of the TrioVS.

For other cost/time saving measures consider:

- LEAP offers multiple choices of Valve Self Wash Stations to aid in cleaning the valve [6]

- Dual Channel Serial Injection with Front Cut (M-002) using Analyst and ICC-CE [7]

- Dual Channel Parallel Injection (M-003) using Cycle Composer Software and Analyst [8]

- “Look Ahead”, sample prep before injection (M-004) using LEAP Shell Software [9]

- Dual Channel Parallel Injection (M-005) using LEAP Shell software [10]

- LEAP Shell Software and application for custom injections and scheduling [11]

This workstation application is based on the CTC PAL X, Y, Z syringe only autosampler robot from LEAP Technologies. This extremely flexible, precise, and adaptable robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your LC or GC requirements. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible automation.