M-005 Dual Channel Parallel Injection - LEAP Shell "(M-Fab)"

From LEAP

| Dual Channel Parallel Injections with LEAP Shell "M-Fab" |

| Application Type | |

| SPECIAL | |

| Application ID | |

| M-005 | |

| Description | |

| High Throughput LC injections alternating onto two analytical columns. |

Contents |

Overview

This configuration provides short cycle times by limiting the acquisition time to just the peaks of interest and regenerating the columns during the acquisition. It uses LEAP Shell Scheduling Software[1] - this application is integrated withAnalyst® Software[2] from Applied Biosystems Inc®. There is a single sample list and allows multiplexing [3] of 2 separate HPLC systems into one mass spectrometer [4].

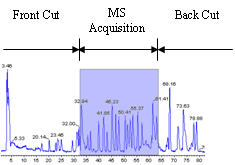

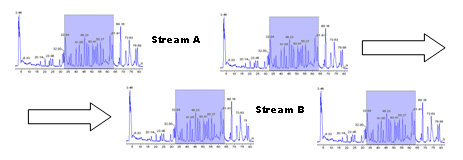

If the peaks of interest come off together in the middle of the gradient (as shown below) then it is possible to utilize the front cut and back cut time to increase throughput.

If injections are staggered in the following way, there is a potential for up to 100% gain:

Hardware Requirements

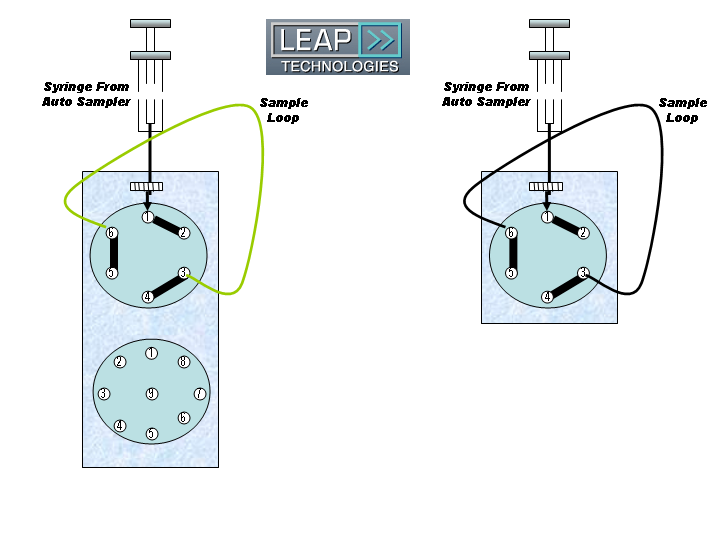

- DoubleStack multiple valve system and a 6 port injection valve with FWS in front of it is required

| Key Benefits |

| Integration with Analyst |

| Single Sample List |

| Staggering of Samples [5] |

| Multiplexes 2 separate LC systems into one Mass Spec |

| Restrictions |

| Does not yet support 21CFR11 |

| Requires Pumps to be integrated with LEAP Shell |

| Code | Application | Control SW | Key Hardware | Key Benefits | Restrictions | GLP |

|---|---|---|---|---|---|---|

| M-005 | Dual Channel Parallel Injection Provides minimum cycle times by limiting the acquisition time to just the peaks of interest and regenerating columns during acquisition | LEAP Shell | * DoubleStack valve * 6 port injection valve * FWS in front of 6 port valve * Gradient Pump * Regeneration pump | * Integration with Analyst Software * Single Sample List * Provides staggering of injections * Multiplexes 2 separate LC systems into on MS | * Does not support 21CFR11 compliance * Requires pumps to be integrated with LEAP Shell | No |

For other cost/time saving measures consider:

- LEAP offers multiple choices of Valve Self Wash Stations to aid in cleaning the valve [6]

- Dual Channel Serial Injection (M-001) using Analyst and ICC-CE [7]

- Dual Channel Serial Injection with Front Cut (M-002) using Analyst and ICC-CE [8]

- “Look Ahead”, sample prep before injection (M-004) using LEAP Shell Software [9]

- Summary of LC Multi Valve Applications [10]

- LEAP Shell Software and application for custom injections and scheduling [11]

This workstation application is based on the CTC PAL X, Y, Z syringe only autosampler robot from LEAP Technologies. This extremely flexible, precise, and adaptable robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your LC or GC requirements. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible automation.

Contact LEAP