M-002 Dual Channel Serial Injection with front cut - Analyst with ICC-CE

From LEAP

Current revision (10:55, 9 June 2009) (view source) (→Contact LEAP) |

|||

| (3 intermediate revisions not shown.) | |||

| Line 6: | Line 6: | ||

|description = High throughput where one column is regenerating while the other is performing analytical separation. An additional valve allows solvent front to be cut to waste. | |description = High throughput where one column is regenerating while the other is performing analytical separation. An additional valve allows solvent front to be cut to waste. | ||

}} | }} | ||

| - | [[Image:LEAP Logo.png|frame|www.leaptec.com<br>www.leapwiki.com]] | + | [[Image:LEAP Logo.png|frame|[http://www.leaptec.com leaptec.com]<br />[http://www.leapwiki.com leapwiki.com]]] |

=== Overview === | === Overview === | ||

This configuration allows the regeneration of one of the analytical columns while the other one is engaged - giving greater efficiency and higher throughput and allows solvent front to be cut to waste with a selector valve. This is run directly from within '''Analyst Software'''[https://products.appliedbiosystems.com/ab/en/US/adirect/ab?cmd=catNavigate2&catID=600927&tab=DetailInfo] from ''Applied Biosystems Inc'' using a Standard LEAP Cycle (requires ICC-CE software) [http://www.leaptec.com/products/lc-related-instruments-and-accessories/ctc-lc-pal-software/instrument-control-components-and-cycle-editor-181.php]. | This configuration allows the regeneration of one of the analytical columns while the other one is engaged - giving greater efficiency and higher throughput and allows solvent front to be cut to waste with a selector valve. This is run directly from within '''Analyst Software'''[https://products.appliedbiosystems.com/ab/en/US/adirect/ab?cmd=catNavigate2&catID=600927&tab=DetailInfo] from ''Applied Biosystems Inc'' using a Standard LEAP Cycle (requires ICC-CE software) [http://www.leaptec.com/products/lc-related-instruments-and-accessories/ctc-lc-pal-software/instrument-control-components-and-cycle-editor-181.php]. | ||

| - | There are 2 pumps needed, one for the gradient run and another (higher flow rate and isocratic) for regeneration. This configuration requires a TrioVS Valve [http://www.leaptec.com/products/lc-related-instruments-and-accessories/rotors-and-inlet-sleeves/pal-trio-vs--valve-system--80.php]. All of the valves must be controlled by the Standard LEAP cycle. <br> ''LEAP can not control the MS Selector valve as part of the cycle.'' | + | There are 2 pumps needed, one for the gradient run and another (higher flow rate and isocratic) for regeneration [http://leapwiki.com/mediawiki/index.php?title=Category:Regeneration]. This configuration requires a TrioVS Valve [http://www.leaptec.com/products/lc-related-instruments-and-accessories/rotors-and-inlet-sleeves/pal-trio-vs--valve-system--80.php]. All of the valves must be controlled by the Standard LEAP cycle. <br> ''LEAP can not control the MS Selector valve as part of the cycle.'' |

[[Image:Empty TRIO.png|frame|TrioVS valve is used. Flow path intentionally left incomplete. Contact LEAP for more information]] | [[Image:Empty TRIO.png|frame|TrioVS valve is used. Flow path intentionally left incomplete. Contact LEAP for more information]] | ||

| Line 68: | Line 68: | ||

| style="border:1px solid blue;"|Yes | | style="border:1px solid blue;"|Yes | ||

|} | |} | ||

| - | |||

=== For other cost/time saving measures consider:=== | === For other cost/time saving measures consider:=== | ||

| Line 76: | Line 75: | ||

* “Look Ahead”, sample prep before injection (M-004) using LEAP Shell Software [http://www.leaptec.com/software/leap-shell-3.php] | * “Look Ahead”, sample prep before injection (M-004) using LEAP Shell Software [http://www.leaptec.com/software/leap-shell-3.php] | ||

* Dual Channel Parallel Injection (M-005) using LEAP Shell software [http://www.leapwiki.com/mediawiki/index.php?title=M-005_Dual_Channel_Parallel_Injection_-_LEAP_Shell_%22(M-Fab)%22] | * Dual Channel Parallel Injection (M-005) using LEAP Shell software [http://www.leapwiki.com/mediawiki/index.php?title=M-005_Dual_Channel_Parallel_Injection_-_LEAP_Shell_%22(M-Fab)%22] | ||

| + | * Summary of LC Multi Valve Applications [http://www.leapwiki.com/mediawiki/index.php?title=Summary_of_LC_Multi_Valve_Applications] | ||

* LEAP Shell Software and application for custom injections and scheduling [http://www.leaptec.com/software/leap-shell-3.php] | * LEAP Shell Software and application for custom injections and scheduling [http://www.leaptec.com/software/leap-shell-3.php] | ||

---- | ---- | ||

| - | [[Image:LEAP Logo.png|frame|www.leaptec.com<br>www.leapwiki.com]] | + | [[Image:LEAP Logo.png|frame|[http://www.leaptec.com leaptec.com]<br />[http://www.leapwiki.com leapwiki.com]]] |

=== Contact LEAP === | === Contact LEAP === | ||

| Line 84: | Line 84: | ||

For additional information about this technique please contact LEAP Technologies for detailed information | For additional information about this technique please contact LEAP Technologies for detailed information | ||

| - | + | [[image:Contact_Info.png|40px]] [http://www.leaptec.com/contact-us.php Contact the LEAP office] | |

<br><br> | <br><br> | ||

[[Category:Analyst with ICC-CE]] | [[Category:Analyst with ICC-CE]] | ||

| + | [[Category:LC Multi Valve Applications]] | ||

Current revision

Overview

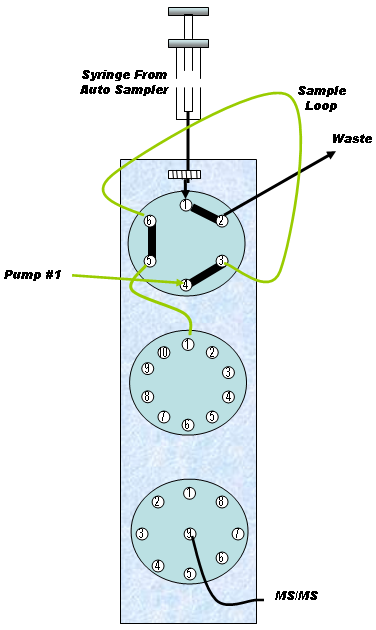

This configuration allows the regeneration of one of the analytical columns while the other one is engaged - giving greater efficiency and higher throughput and allows solvent front to be cut to waste with a selector valve. This is run directly from within Analyst Software[1] from Applied Biosystems Inc using a Standard LEAP Cycle (requires ICC-CE software) [2].

There are 2 pumps needed, one for the gradient run and another (higher flow rate and isocratic) for regeneration [3]. This configuration requires a TrioVS Valve [4]. All of the valves must be controlled by the Standard LEAP cycle.

LEAP can not control the MS Selector valve as part of the cycle.

| Key Benefits |

| Saving of Reagent time (Back cut) [5] |

| Increase throughput at little cost |

| Control is all within Analyst Software |

| Compliance not affected |

| Avoids contaminating MS inlet with early eluting compounds and solvent |

| Restrictions |

| Cannot do "Look Ahead"[6] |

| Injections are not staggered[7] |

| Peaks of interest must come off early |

| Columns may perform slightly different on alternating samples |

| Requires TrioVS valve |

| Code | Application | Control SW | Key Hardware | Key Benefits | Restrictions | GLP |

|---|---|---|---|---|---|---|

| M-002 | Dual Channel Serial Injection with Front Cut Provides shorter cycle times by regenerating columns during next analytical run and diverts the solvent front to waste | Analyst with ICC-CE | * Trio VS * Gradient Pump * Regeneration pump | * Saving of regeneration time(Back Cut) * Increase throughput at little cost * Control is all within Analyst * Compliance is not affected * Avoids contaminating MS inlet with early eluting compounds and Solvent | * Can not do "Look Ahead" * Injections are not staggered * Peaks of interest must come of early * Columns may perform slightly differently on alternating samples | Yes |

For other cost/time saving measures consider:

- LEAP offers multiple choices of Valve Self Wash Stations to aid in cleaning the valve [8]

- Dual Channel Serial Injection (M-001) using Analyst and ICC-CE [9]

- Dual Channel Parallel Injection (M-003) using Cycle Composer Software and Analyst [10]

- “Look Ahead”, sample prep before injection (M-004) using LEAP Shell Software [11]

- Dual Channel Parallel Injection (M-005) using LEAP Shell software [12]

- Summary of LC Multi Valve Applications [13]

- LEAP Shell Software and application for custom injections and scheduling [14]

Contact LEAP

For additional information about this technique please contact LEAP Technologies for detailed information