DLW (Dynamic Load and Wash)

From LEAP

| DLW (Dynamic Load and Wash) for Fast and Clean LC/MS Loading |

| Application Type | |

| Washing LC Valve | |

| Application ID | |

| DLW (Dynamic Load and Wash) for Fast and Clean LC/MS Loading | |

| Description | |

Contents |

DLW (Dynamic Load and Wash) for Fast and Clean LC/MS Loading

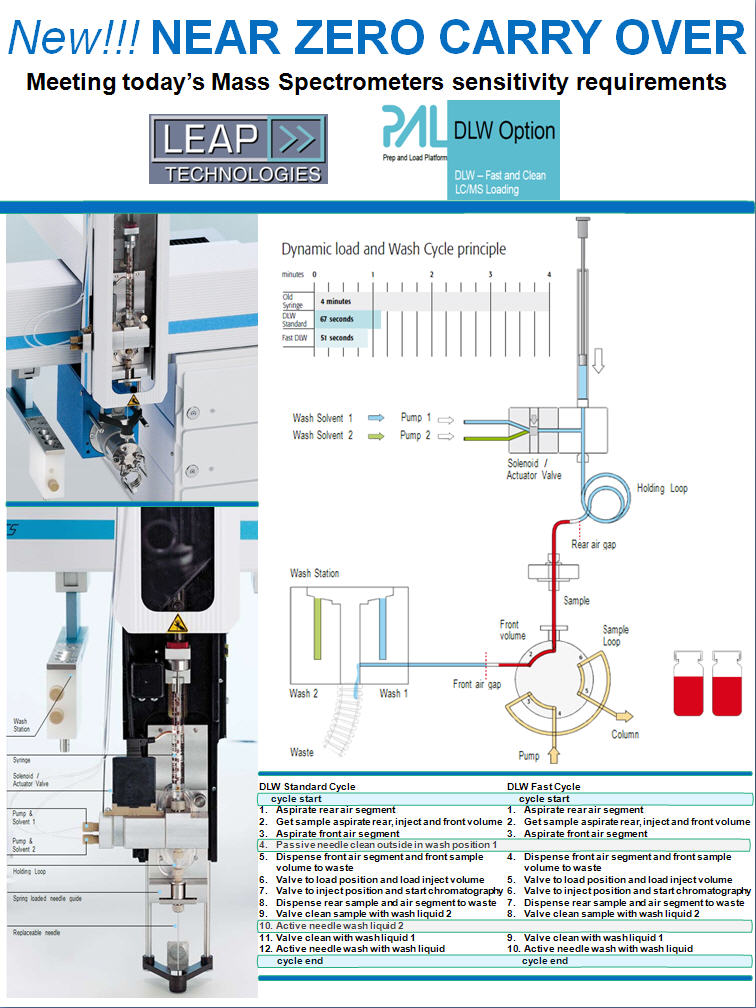

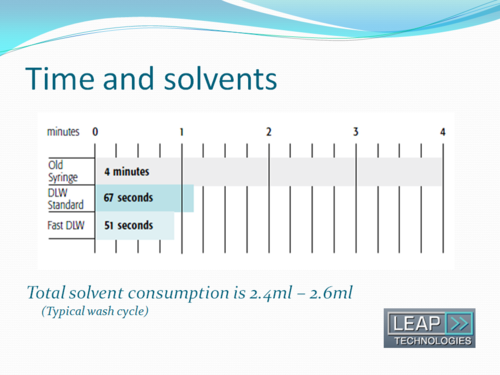

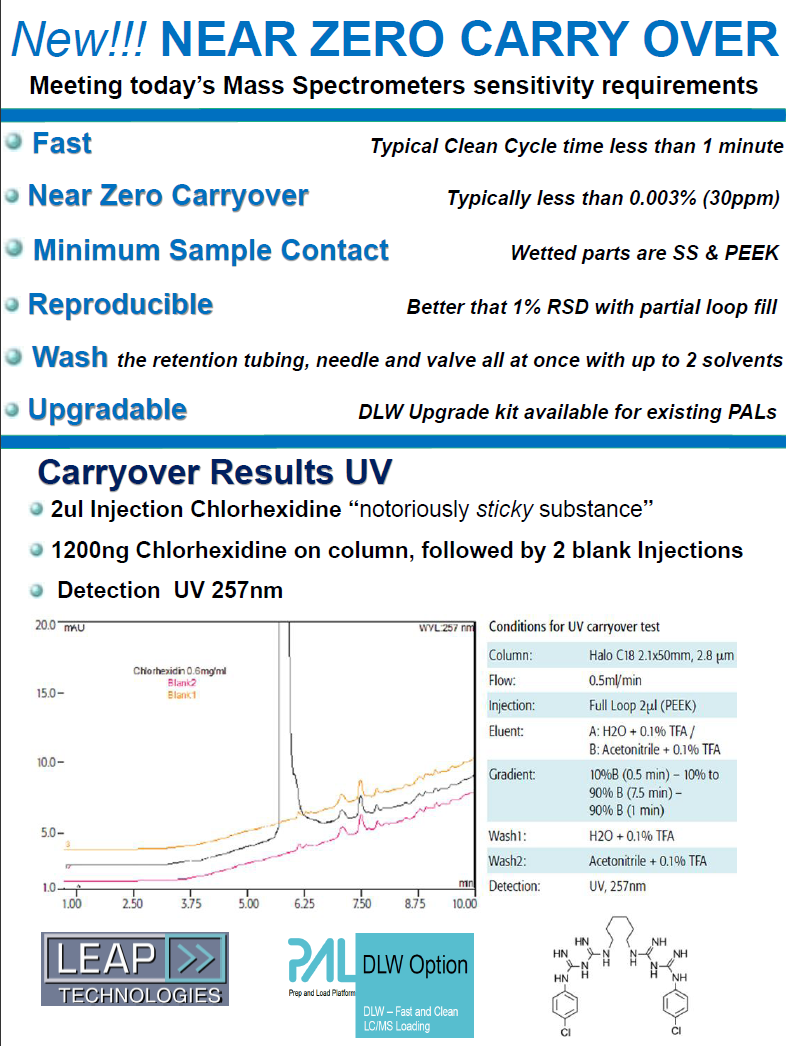

- The DLW is designed for today’s most sensitive MS instruments this completely new injection and wash concept gives Near Zero Carryover and can drastically reduced cycle times.

Main Features

- Near Zero Carryover - Typically less than 0.003%

- Reduced wash cycling times- Typical Clean Cycle time less that 1 minute (Fast Cycle)

- Inert sampling path - No contact with syringe, only PEEK tubing and stainless steel

- Reproducible - < 1% RSD

- Minimum sample contact - wetted parts are stainless steel and PEEK

- Two Solvent Wash - Complete cleaning from the opposite direction of sampling

- Flexible - HPLC and UHPLC applications

- Robust - Spring loaded syringe needle positioning

- Can be run from Analyst 1.5

- Upgradable - Existing PAL systems can be upgraded

The features include:

- A new state-of-the-art new electronics board

- Dynamic Load and Wash (DLW) concept

This results in:

- Keeping sample away from the syringe, plus fast, effective washing of all wetted path

- Near-zero carryover results from run to run

- Larger memory capacity for more objects

- Faster basic motor speeds

- Controls additional solenoid valves and other accessories

- Externally exchangeable fuse, which protects electronics

- Ethernet as well as RS 232 interface

- New firmware 4.x not available for old boards

CTC Analytics, the manufacturer of the PAL sampling and high throughput systems, has announced the release of the Dynamic Load and Wash (DLW). This upgrade has undergone rigorous customer testing and has proven to be extremely effective in removing carryover. The DLW isolates the syringe from the sample and has the ability to rapidly and thoroughly wash tubing, needle and valve with two different solvents. The DLW will be offered in an upgrade kit as well as on all new HTC and HTS PALs as an option.

![]() LEAP is proud to introduce the newest PAL's the HTC-xt

LEAP is proud to introduce the newest PAL's the HTC-xt

![]() LEAP is proud to introduce the newest PAL's the HTS-xt

LEAP is proud to introduce the newest PAL's the HTS-xt

Who may benefit:

- High throughput users- Fast wash cycles

- High Sensitivity Detection users

- Existing users of PAL – xt Upgrade Kit is available from LEAP

- New users – Looking for a Faster Cleaner Autosampler

![]() Animation of Fast Cycle for DLW for PAL

Animation of Fast Cycle for DLW for PAL

PRINT Brochure

![]() PDF Brochure of DLW for CTC PAL

PDF Brochure of DLW for CTC PAL

![]() PDF of DLW Comparison of Cycles

PDF of DLW Comparison of Cycles

![]() PDF of DLW Data

PDF of DLW Data

Accessories for the PAL

![]() Other Accessories for PAL Robots

Other Accessories for PAL Robots

LEAP strives to find total solutions for analytical lab automation by automating analytical processes for small and large molecules in extracted liquids, solids, and recently in human, animal and plant tissues. We provide the precise robotics and efficient sample prep required by modern measurement techniques such as MALDITOF mass spectroscopy. Our newest specialty customization of CTC Analytics’ PAL features small workstations that can perform complex liquid handling tasks including HPLC-Purification, SPE, filtration, weighing, heating and stirring. They can be configured as stand alone units or integrated for “just in time” sample prep for LC-MS or GC-MS analysis.

LEAP provides automated workstation instrumentation solutions based on the LEAP CTC PAL X, Y, Z syringe only autosampler robot from LEAP Technologies. This extremely flexible, precise, and adaptable liquid handling robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your UHPLC, LC or GC chromatography.LEAP offers full support and service for the PAL platform in addition to being able to write custom macros, cycles, and scheduling to your applications. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible pipetting automation solutions.

Contact LEAP

For additional information about LEAP and the PAL Platform, please contact LEAP Technologies. |