Tobacco Filtration - 96 Well Plate Filtration

From LEAP

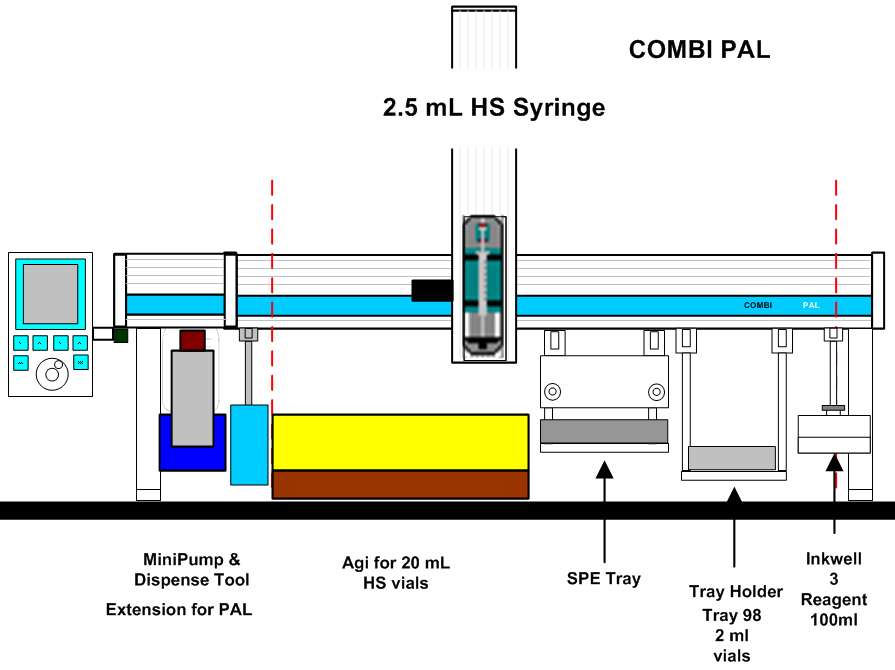

Original tobacco samples will be placed in 20ml vials. These vials will be loaded into a shaker tray that will also heat and agitate the samples at the appropriate time. The PAL will 15ml of solvent will be added[1] to each sample in the batch. Then 50ul of internal standard will also be added to each sample in the batch. After these two additions, the samples will be heated and agitated for a period of time specified by the user. Once the incubation period expires, 1.5ml of each sample will be filtered through a 0.45 micron PTFE filter. Then 1ml of each filtered sample will be transferred to a separate 2ml vial for off-line analysis.

Project Ref: LS-C10013

- Additional info on 96 well Filtration [2]

- Additional info on Large Volume Dispensing [3]

- Additional info on Mixing of Samples [4]

LEAP provides automated workstation instrumentation solutions based on the LEAP CTC PAL X, Y, Z syringe only autosampler robot from LEAP Technologies. This extremely flexible, precise, and adaptable liquid handling robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your UHPLC, LC or GC chromatography.LEAP offers full support and service for the PAL platform in addition to being able to write custom macros, cycles, and scheduling to your applications. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible pipetting automation solutions.

Contact LEAP

For additional information about the PAL and the application, please contact LEAP Technologies. |