Tobacco Filtration

From LEAP

(Difference between revisions)

| Line 1: | Line 1: | ||

| - | + | {{LSApp | |

| + | |name = Tobacco Analysis | ||

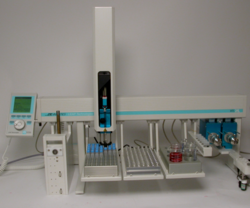

| + | |image = Whatman_Press_PAL_photo.png | ||

| + | |type = '''Applications''' | ||

| + | |id = | ||

| + | |description = Automated Filtration with Press for UniPrep vials by Whatman | ||

| + | }} | ||

| + | === Overview === | ||

| + | '''Tobacco Analysis''' is an area that LEAP has lots of experience. These applications illustrates the power of LEAP’s unique control software to incorporate extended functionality to the PAL robot.<br><br> | ||

| + | Some of what LEAP can do with the PAL for Tobacco Analysis… | ||

| + | * Different filtration modes | ||

| + | * Overlapped staggered processing of all samples for higher throughput | ||

| + | * Twin PAL option for greater capacity and flexibility and a single sample list | ||

| + | * Multiple reagent reservoirs and large sample vial capacity | ||

| + | * Multiple heated zones for different temperature reactions | ||

| + | * Direct injection to LC or GC | ||

| + | * Balance integration for weighing of solid product and internal standard | ||

| + | * Weight checking, over or under weight vials are skipped | ||

| + | * Barcode checking, mismatched vials are not processed | ||

| + | * Data reporting to log files | ||

| + | * GC fail safe mode – if GC goes down during a run, samples are still processed and stored for later analysis | ||

| + | <br> | ||

| + | ---- | ||

| + | Some of the applications that LEAP has done in this area is: | ||

| + | * [http://www.leapwiki.com/mediawiki/index.php?title=Filtering_of_Samples Filtering of Samples] | ||

| - | [ | + | * [http://www.leapwiki.com/mediawiki/index.php?title=GC_Headspace GC Headspace] |

| + | * [http://www.leapwiki.com/mediawiki/index.php?title=Multi_Headspace_Extractions Multiple Headspace Extractions] | ||

| - | + | * [http://www.leapwiki.com/mediawiki/index.php?title=SPME SPME] | |

| + | * [http://www.leapwiki.com/mediawiki/index.php?title=LC_Multi-Valve_Applications LC Applications] | ||

| - | * | + | * [http://www.leapwiki.com/mediawiki/index.php?title=Balance_PAL Automated Weighing] |

| - | * | + | * [http://www.leapwiki.com/mediawiki/index.php?title=Agitation_of_Samples Agitation & Mixing] |

| - | + | ----- | |

| + | Specific example applications: | ||

| - | + | * [http://www.leapwiki.com/mediawiki/index.php?title=Tobacco_Filtration_-_96_Well_Plate_Filtration Tobacco Filtration 96 well plate Example System] | |

| - | * | + | |

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | * [http://www.leapwiki.com/mediawiki/index.php?title=Tobacco_Filtration_-_Large_Volume_Flask Large Tobacco Sample Volume Filtration Example System] | |

| - | + | ||

| + | |||

| + | {{logo}} | ||

=== Contact LEAP === | === Contact LEAP === | ||

{{contact|topic=LEAP and the PAL Platform}} | {{contact|topic=LEAP and the PAL Platform}} | ||

| - | [[Category: | + | [[Category:Glossary]] |

| - | [[Category: | + | [[Category:Accessories]] |

| + | [[Category:Filtering of Samples]] | ||

Revision as of 01:08, 29 October 2009

| Tobacco Analysis |

| Application Type | |

| Applications | |

| Application ID | |

| Description | |

| Automated Filtration with Press for UniPrep vials by Whatman |

Overview

Tobacco Analysis is an area that LEAP has lots of experience. These applications illustrates the power of LEAP’s unique control software to incorporate extended functionality to the PAL robot.

Some of what LEAP can do with the PAL for Tobacco Analysis…

- Different filtration modes

- Overlapped staggered processing of all samples for higher throughput

- Twin PAL option for greater capacity and flexibility and a single sample list

- Multiple reagent reservoirs and large sample vial capacity

- Multiple heated zones for different temperature reactions

- Direct injection to LC or GC

- Balance integration for weighing of solid product and internal standard

- Weight checking, over or under weight vials are skipped

- Barcode checking, mismatched vials are not processed

- Data reporting to log files

- GC fail safe mode – if GC goes down during a run, samples are still processed and stored for later analysis

Some of the applications that LEAP has done in this area is:

Specific example applications:

Contact LEAP

For additional information about LEAP and the PAL Platform, please contact LEAP Technologies. |