Sandbox

From LEAP

| Semi-Solid Workstation |

| Application Type | |

| SPECIAL | |

| Application ID | |

| Semi-Solid Workstation PAL | |

| Description | |

| Semi-Solid Workstation Sample Preperation |

Contents |

General Description

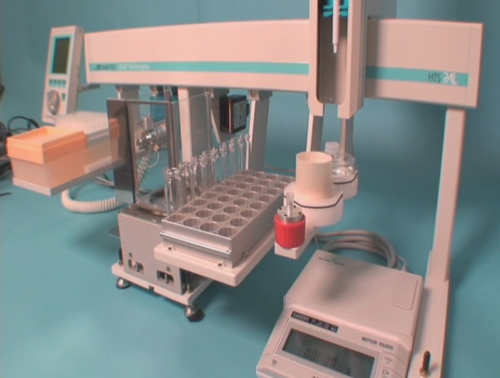

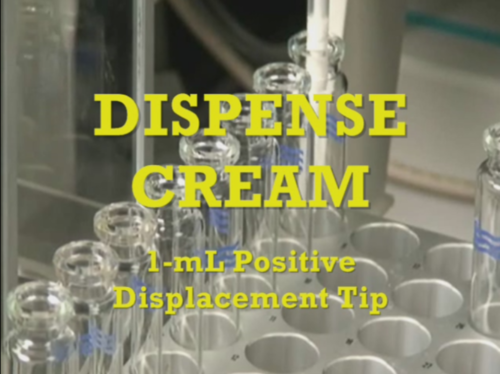

The Semi-Solid Workstation is designed to automate the weighing of samples in 20ml or 10ml vials. The application will tare vials, then the system will add a semi solid 'cream' to each vial with individual disposable tips. Once the samples in the ample list are dispensed each vial is re-weighed and calculation and report of the net sample weight. A barcode scanner is included in the setup, and scanning is an option in the method. Values for sample ID, barcode, tare weight and sample weight are recorded in a text file. Barcode validation is optional if the codes do not match from the tare step to the weigh step, the sample is flagged in the output file. It is designed so that the output file can be imported into the sample list of another PAL workstation which will use the sample ID and weight information to do an automatic proportional dilution and filtration step.

Significant Markets

- Pharmaceutical - QA QC

What is an Semi-Solid experiment ?

Performing dispensing of semi-solid liquids manually involves the tedious task of manually pipetting a cream or similar viscous material into tared vials and then reweighing them to determine the exact weight afterwords.

Overview of Semi-Solid PAL System

Semi-Solid Workstation is an easy-to-use, system that provides an automated process for the scheduling and repetitive execution of weighing and dispensing workflow. By use of the advanced LEAP Shell scheduling software experimental design is simplified and reliable.

What does the Semi-Solid PAL do?

The instrument has two cooled zones for sample storage and labeling. The injection valve is chilled to 1 degree Celsius and includes a solvent pre-chiller and column selection valve for in-line protein digestion.

A typical experiment would consist of around a dozen time points for each protein sample, ranging from 10 seconds to 8 hours. The PAL system will schedule the experiments and perform each of the following 3 steps for each time point and sample:

Labeling The protein is mixed with a Deuterium reagent and incubated for a precisely timed interval at room temperature.

Quenching The labeling reaction is stopped by transferring a volume of the mixture to an excess of quenching reagent in a pre-cooled vessel.

Injection A measured portion of the quenched reactants is injected into a multi-column, multi-valve LCMS system. This step is synchronized with the analytical system using hardware signals. The PAL will inject samples as the LCMS system becomes ready. Labeled and quenched reactants are held in the cooled stack until they have been injected and analyzed.

The system is equipped with a gripper, which can pick up the vial with or without cup and transfer to and back from the balance.

Software Control

LEAP has developed a scheduling application using their proprietary software “LEAP Shell” which will automate the above labeling steps, as well as the injection to the MS and the associated chromatography.

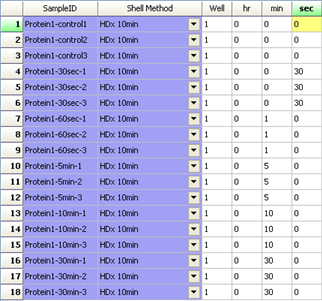

LEAP Shell Screen Shot 1: User interface to set up the labelling experiment:

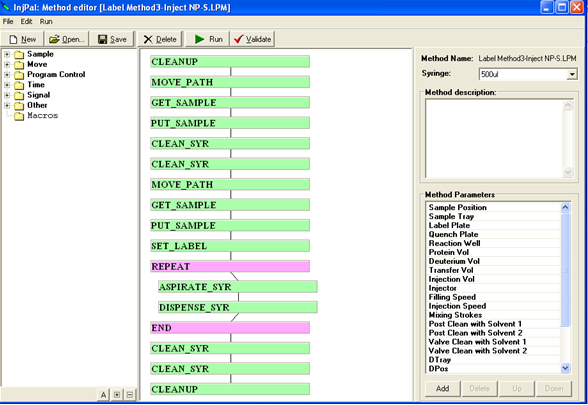

LEAP Shell Screen Shot 2: Powerfull editor for the PAL Methods:

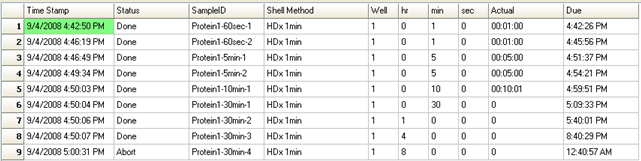

LEAP Shell Screen Shot 3: Run-time display of the labelling experiment with actual times:

Useful links

![]() HXMS.com A good general reference site on HD Exchange theory and practice

HXMS.com A good general reference site on HD Exchange theory and practice

![]() ASMS Interest Group - Hydrogen Exchange and Covalent Labeling

ASMS Interest Group - Hydrogen Exchange and Covalent Labeling

![]() LEAP Website H/D-x product description

LEAP Website H/D-x product description

Publications

![]() American Chemical Society 2006. Chalmers

American Chemical Society 2006. Chalmers

![]() Poster from ASMS 2006

Poster from ASMS 2006

![]() Poster ASMS 2006 Washington Univ. In St Louis

Poster ASMS 2006 Washington Univ. In St Louis

Other Reference material

![]() LEAP HDX Application Note

LEAP HDX Application Note

![]() Collaboration between LEAP & ExSAR

Collaboration between LEAP & ExSAR

![]() Comparison of Data Processing software

Comparison of Data Processing software

LEAP provides automated workstation instrumentation solutions based on the LEAP CTC PAL X, Y, Z syringe only autosampler robot from LEAP Technologies. This extremely flexible, precise, and adaptable liquid handling robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your UHPLC, LC or GC chromatography.LEAP offers full support and service for the PAL platform in addition to being able to write custom macros, cycles, and scheduling to your applications. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible pipetting automation solutions.

Contact LEAP

For additional information about LEAP and the PAL Platform, please contact LEAP Technologies. |