Sandbox

From LEAP

Current revision (13:14, 23 March 2011) (view source) |

|||

| (28 intermediate revisions not shown.) | |||

| Line 1: | Line 1: | ||

| - | + | {{LSApp | |

| + | |name = Sandbox | ||

| + | |image = PAL.png | ||

| + | |type = Base for other pages | ||

| + | |id = Development page | ||

| + | |description = This page is a generic template for development | ||

| + | }} | ||

| - | + | {{logo}} | |

| + | === Company Description === | ||

| - | + | LEAP Technologies, Inc. was founded in 1989 as an [http://leapwiki.com/mediawiki/index.php?title=Category:PAL autosampler] company serving the [http://leapwiki.com/mediawiki/index.php?title=Category:Gas_Chromatography GC] and GC–MS markets. Since then, LEAP has expanded into front-end sample handling for all areas of [http://www.leapwiki.com/mediawiki/index.php?title=Category:Chromatography chromatography] and [http://www.leapwiki.com/mediawiki/index.php?title=Category:Mass_spectrometry mass spectroscopy], including LC/MS/MS and [http://www.leapwiki.com/mediawiki/index.php?title=Category:MALDI MALDI-MS] as well as robotics for proteomics and fiber optic UV technology for tablet dissolution. LEAP strives to find total solutions for analytical lab automation. One of the major components in LEAP's approach to automation solutions is with the [http://leapwiki.com/mediawiki/index.php?title=Category:PAL PAL] X,Y,Z robot. | |

| - | + | === The LEAP Story === | |

| - | + | ||

| - | + | ||

| - | [[ | + | LEAP is experienced in providing automation solutions for any process that gathers, treats and delivers samples to an analytical process. Liquid Handling is in most cases involved but we are not limited to that. We can also move,[http://www.leapwiki.com/mediawiki/index.php?title=Balance_PAL weigh] and image objects. Liquid handling includes spraying and printing besides the usual measuring, pipetting, injecting, [http://www.leapwiki.com/mediawiki/index.php?title=Mixing_of_Samples mixing ], [http://leapwiki.com/mediawiki/index.php?title=Cooling_and_Heating_Sample_Storage heating ] or sampling of a variety of liquids. We have the ability to design, engineer, deliver and support simple but unique or complex but simple to use systems. The [http://www.leapwiki.com/mediawiki/index.php?title=Category:LEAP_Shell LEAP Shell] software lets us create solution-specific sample lists and shell methods that synchronize all instruments involved. LEAP Shell is used for LC/LCMS and stand-alone workstations. LEAP uses [http://www.leapwiki.com/mediawiki/index.php?title=Category:Chronos Chronos Mastersoftware]for GC and GC-MS integrations. Currently, Chronos integrates with Thermo Electron Xcalibur 1.4 and 2.0 GC & Agilent GC and MSD ChemStation. Further data system packages are begin integrate with Chronos so check with LEAP to see if your is.<br> |

| + | We can provide complete locked-down systems to Value Added Resellers (VARs). Combinations of instruments that we can supply are robotic sampling devices and LC pumps as front-end to LC-MS systems. Single and [http://www.leapwiki.com/mediawiki/index.php?title=Category:Dual_Channel dual channel] LC to one MS that save [http://www.leapwiki.com/mediawiki/index.php?title=Category:Cycle_Times cycle time] and therefore increase throughput are becoming standard Frontend Automation Bundles (FABs). LEAP has available a proven SDK for [http://leapwiki.com/mediawiki/index.php?title=Category:PAL PAL] integration into your [http://www.leapwiki.com/mediawiki/index.php?title=Category:Data_System data system] software.<br> | ||

| + | One of LEAP's fundamental business philosophies is to build strong client relationships by knowing our customers and responding to their specific needs with superior personal service whether you have one [http://leapwiki.com/mediawiki/index.php?title=Category:PAL PAL] or are VAR of [http://leapwiki.com/mediawiki/index.php?title=Categroy:Theyll_say_its_a_LEAP LEAP's]. | ||

| + | ---- | ||

| + | ---- | ||

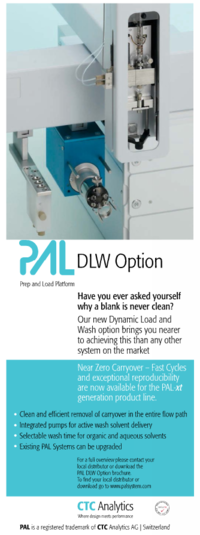

| - | + | [[Image:CTC DLW LCGC Magazine April 2010.png |200px|left|UHPLC Seminar by LEAP Technologies]] | |

| - | + | ||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | ''' | + | '''Register for the DLW & HTS, HTC-xt Webinar on Tuesday August 24th, 2010'''<br> |

| - | + | Free Webinar discussing new, real life experience with carry-over reduction using the new PAL-xt models and DLW upgrades, the new “Dynamic Load and Wash” system for the PAL. | |

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | For those of you who struggle with carryover when injecting “sticky” samples, or for those of you wishing to improve the general efficiency of your wash with faster wash cycles and minimal solvent usage, LEAP is offering this new system wash called the “DLW”. During the Webinar we will illustrate how this new device works so effectively, we will discuss its setup and new wash parameters. We will also summarize real-world experiences of carryover data observed at customer sites. | |

| + | LEAP is now offering the new “xt” version of the PAL. We will highlight the main differences and advantages of this instrument. | ||

| + | <br><br> | ||

| + | The Webinar will be held both ''Tuesday August 24th'' and Tuesday August 31st at 1pm EST and will last approximately 30 minutes. | ||

| + | <br><br> | ||

| + | [[image: Info icon.png|40px]] [http://www.leaptec.com/exhibits/_events/08-24-2010/webinar-dlw-and-htshtc-xt-7102.php Sign Up for DLW & "-xt" Webinar] | ||

<br> | <br> | ||

| - | + | Please call us if you have any questions at 800.229.8814 if you have any questions. | |

| - | + | ||

| - | + | ||

<br> | <br> | ||

| + | Download a flyer:<br> | ||

| + | [[image: Info icon.png|40px]] [[:Media:DLW_Webinar_flyer_August_2010.pdf | LEAP Webinar Flyer for DLW & "-xt" August 24, 2010]]<br> | ||

| + | <br><br><br><br><br><br><br><br><br><br><br><br><br><br> | ||

| + | ---- | ||

| + | [[image:UHPLC_System_1.png|200px|left|UHPLC Seminar by LEAP Technologies]] | ||

| + | |||

| + | '''Register for the UHPLC-MS Automation August 26th, 2010 1 pm EDST'''<br> | ||

| + | A Free webinar introducing the new UHPLC-MS Automation Package for Analyst (AB Sciex) from LEAP.<br> | ||

| + | |||

| + | The golden combination of Pump and Autosampler called “Flex-a-PAL” beats other combination's with reliability, flexibility and convenience? Combine the LEAP PAL with the FX-15 UHPLC pump and be set for years to come. | ||

| + | |||

| + | Learn what this combination will do for you. LEAP offers the complete system or upgrades for PALs and add the FX-15 UHPLC pump for all your LC-MS needs. If you use small particle columns for a100% or only 20% of your LC methods you are all set to change from UHPLC to traditional columns in practically no time without re-plumbing your system. Learn more about how your PAL can be upgraded to near zero carry-over performance and to being completely UHPLC capable. | ||

| + | <br><br> | ||

| + | Webinar will be held '' August 26th, 2010 at 1pm EDST'' and will last 60 minutes. | ||

| + | <br><br> | ||

| + | [[image: Info icon.png|40px]] [http://www.leaptec.com/exhibits/_events/08-26-2010/webinar--uhplc-ms-automation-7103.php Sign Up for UHPLC Webinar] | ||

| + | <br><br> | ||

| + | Please call us at 800.229.8814 if you have any questions. | ||

| + | <br> | ||

| + | Download a flyer:<br> | ||

| + | [[image: Info icon.png|40px]] [[:Media:UHPLC_Webinar_flyer_8_18__8_26.pdf | LEAP Webinar Flyer for UHPLC August 26, 2010]]<br> | ||

| + | <br> | ||

| + | |||

| + | |||

| + | ---- | ||

| + | [[Image:XChange on 7890.png|200px|left|XChange by LEAP Technologies]] | ||

| + | [[Image:XChange on 7890 B.png|200px|left|XChange by LEAP Technologies]] | ||

| + | [[Image:XChange on 7890 A.png|200px|left|XChange by LEAP Technologies]] | ||

---- | ---- | ||

| Line 59: | Line 72: | ||

=== Contact LEAP === | === Contact LEAP === | ||

{{contact|topic=LEAP and the PAL Platform}} | {{contact|topic=LEAP and the PAL Platform}} | ||

| - | + | New XCHANGE® Option for automated syringe exchange | |

| - | + | ||

| + | 20. January 2011 | ||

| + | CTC Analytics has - in collaboration with SGE Analytical Science - released the new XCHANGE® Option which is fully implemented on the PAL-xt platforms. | ||

| + | Automated syringe exchange enables new application possibilities with enhanced flexibility. | ||

| + | Main features are: | ||

| + | • Injection of small and large volumes in one sample sequence | ||

| + | • Adding of internal standards without cross contamination | ||

| + | • Preventative exchange of syringe when using harmful media | ||

| + | • Choice of 9 different syringe volumes | ||

| + | • Serial dilution | ||

| + | For more information please go to XCHANGE® Option | ||

| + | XCHANGE® Option | ||

| + | |||

| + | PAL COMBI-xt equipped with XCHANGE Option | ||

| + | Injection of small and large volumes in one sample sequence | ||

| + | Adding internal standards without cross contamination | ||

| + | Preventative exchange of syringe when using harmful media | ||

| + | Choice of 9 different syringe volumes | ||

| + | Serial dilution | ||

| + | |||

| + | CTC Analytics has - in collaboration with SGE Analytical Science - released the new XCHANGE® Option which is fully implemented on the PAL-xt platforms. | ||

| + | Automated syringe exchange enables new application possibilities with enhanced flexibility. | ||

| + | The XCHANGE® coupling system secures and locks the syringe in place. This is achieved by a mating mechanical piece that captures the syringe and a magnet that automatically aligns – eliminating the need for springs, screws, or alignment gauges. Once engaged the syringe is locked into position requiring zero holding force. | ||

| + | |||

| + | Order details | ||

| + | Part no.: PAL XCHANGEOpt | ||

| + | Consisting of: 1pc XCHANGE ® Park Station assembly | ||

| + | 1pc Set of LC needles | ||

| + | 1pc Plunger coupling | ||

| + | 1pc XCHANGE coupling | ||

| + | 1pc Set of Park Station mounting arms | ||

| + | 1pc Active needle guide assembly | ||

| + | 4pcs of XCHANGE ® syringes (10µl, 100µl, 1ml and 5ml) | ||

| + | 1pc Alignment tool | ||

| + | 1pc PAL-xt System CD (requires PAL Firmware 4.2.x) | ||

Current revision

| Sandbox |

| Application Type | |

| Base for other pages | |

| Application ID | |

| Development page | |

| Description | |

| This page is a generic template for development |

Company Description

LEAP Technologies, Inc. was founded in 1989 as an autosampler company serving the GC and GC–MS markets. Since then, LEAP has expanded into front-end sample handling for all areas of chromatography and mass spectroscopy, including LC/MS/MS and MALDI-MS as well as robotics for proteomics and fiber optic UV technology for tablet dissolution. LEAP strives to find total solutions for analytical lab automation. One of the major components in LEAP's approach to automation solutions is with the PAL X,Y,Z robot.

The LEAP Story

LEAP is experienced in providing automation solutions for any process that gathers, treats and delivers samples to an analytical process. Liquid Handling is in most cases involved but we are not limited to that. We can also move,weigh and image objects. Liquid handling includes spraying and printing besides the usual measuring, pipetting, injecting, mixing , heating or sampling of a variety of liquids. We have the ability to design, engineer, deliver and support simple but unique or complex but simple to use systems. The LEAP Shell software lets us create solution-specific sample lists and shell methods that synchronize all instruments involved. LEAP Shell is used for LC/LCMS and stand-alone workstations. LEAP uses Chronos Mastersoftwarefor GC and GC-MS integrations. Currently, Chronos integrates with Thermo Electron Xcalibur 1.4 and 2.0 GC & Agilent GC and MSD ChemStation. Further data system packages are begin integrate with Chronos so check with LEAP to see if your is.

We can provide complete locked-down systems to Value Added Resellers (VARs). Combinations of instruments that we can supply are robotic sampling devices and LC pumps as front-end to LC-MS systems. Single and dual channel LC to one MS that save cycle time and therefore increase throughput are becoming standard Frontend Automation Bundles (FABs). LEAP has available a proven SDK for PAL integration into your data system software.

One of LEAP's fundamental business philosophies is to build strong client relationships by knowing our customers and responding to their specific needs with superior personal service whether you have one PAL or are VAR of LEAP's.

Register for the DLW & HTS, HTC-xt Webinar on Tuesday August 24th, 2010

Free Webinar discussing new, real life experience with carry-over reduction using the new PAL-xt models and DLW upgrades, the new “Dynamic Load and Wash” system for the PAL.

For those of you who struggle with carryover when injecting “sticky” samples, or for those of you wishing to improve the general efficiency of your wash with faster wash cycles and minimal solvent usage, LEAP is offering this new system wash called the “DLW”. During the Webinar we will illustrate how this new device works so effectively, we will discuss its setup and new wash parameters. We will also summarize real-world experiences of carryover data observed at customer sites.

LEAP is now offering the new “xt” version of the PAL. We will highlight the main differences and advantages of this instrument.

The Webinar will be held both Tuesday August 24th and Tuesday August 31st at 1pm EST and will last approximately 30 minutes.

![]() Sign Up for DLW & "-xt" Webinar

Sign Up for DLW & "-xt" Webinar

Please call us if you have any questions at 800.229.8814 if you have any questions.

Download a flyer:

![]() LEAP Webinar Flyer for DLW & "-xt" August 24, 2010

LEAP Webinar Flyer for DLW & "-xt" August 24, 2010

Register for the UHPLC-MS Automation August 26th, 2010 1 pm EDST

A Free webinar introducing the new UHPLC-MS Automation Package for Analyst (AB Sciex) from LEAP.

The golden combination of Pump and Autosampler called “Flex-a-PAL” beats other combination's with reliability, flexibility and convenience? Combine the LEAP PAL with the FX-15 UHPLC pump and be set for years to come.

Learn what this combination will do for you. LEAP offers the complete system or upgrades for PALs and add the FX-15 UHPLC pump for all your LC-MS needs. If you use small particle columns for a100% or only 20% of your LC methods you are all set to change from UHPLC to traditional columns in practically no time without re-plumbing your system. Learn more about how your PAL can be upgraded to near zero carry-over performance and to being completely UHPLC capable.

Webinar will be held August 26th, 2010 at 1pm EDST and will last 60 minutes.

![]() Sign Up for UHPLC Webinar

Sign Up for UHPLC Webinar

Please call us at 800.229.8814 if you have any questions.

Download a flyer:

![]() LEAP Webinar Flyer for UHPLC August 26, 2010

LEAP Webinar Flyer for UHPLC August 26, 2010

LEAP strives to find total solutions for analytical lab automation by automating analytical processes for small and large molecules in extracted liquids, solids, and recently in human, animal and plant tissues. We provide the precise robotics and efficient sample prep required by modern measurement techniques such as MALDITOF mass spectroscopy. Our newest specialty customization of CTC Analytics’ PAL features small workstations that can perform complex liquid handling tasks including HPLC-Purification, SPE, filtration, weighing, heating and stirring. They can be configured as stand alone units or integrated for “just in time” sample prep for LC-MS or GC-MS analysis. LEAP provides automated workstation instrumentation solutions based on the LEAP CTC PAL X, Y, Z syringe only autosampler robot from LEAP Technologies. This extremely flexible, precise, and adaptable liquid handling robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your UHPLC, LC or GC chromatography.LEAP offers full support and service for the PAL platform in addition to being able to write custom macros, cycles, and scheduling to your applications. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible pipetting automation solutions.

Contact LEAP

For additional information about LEAP and the PAL Platform, please contact LEAP Technologies. |

New XCHANGE® Option for automated syringe exchange

20. January 2011 CTC Analytics has - in collaboration with SGE Analytical Science - released the new XCHANGE® Option which is fully implemented on the PAL-xt platforms. Automated syringe exchange enables new application possibilities with enhanced flexibility. Main features are: • Injection of small and large volumes in one sample sequence • Adding of internal standards without cross contamination • Preventative exchange of syringe when using harmful media • Choice of 9 different syringe volumes • Serial dilution For more information please go to XCHANGE® Option XCHANGE® Option

PAL COMBI-xt equipped with XCHANGE Option Injection of small and large volumes in one sample sequence Adding internal standards without cross contamination Preventative exchange of syringe when using harmful media Choice of 9 different syringe volumes Serial dilution

CTC Analytics has - in collaboration with SGE Analytical Science - released the new XCHANGE® Option which is fully implemented on the PAL-xt platforms. Automated syringe exchange enables new application possibilities with enhanced flexibility. The XCHANGE® coupling system secures and locks the syringe in place. This is achieved by a mating mechanical piece that captures the syringe and a magnet that automatically aligns – eliminating the need for springs, screws, or alignment gauges. Once engaged the syringe is locked into position requiring zero holding force.

Order details Part no.: PAL XCHANGEOpt Consisting of: 1pc XCHANGE ® Park Station assembly 1pc Set of LC needles 1pc Plunger coupling 1pc XCHANGE coupling 1pc Set of Park Station mounting arms 1pc Active needle guide assembly 4pcs of XCHANGE ® syringes (10µl, 100µl, 1ml and 5ml) 1pc Alignment tool 1pc PAL-xt System CD (requires PAL Firmware 4.2.x)