MS tuning & analytical column combination - Analyst

From LEAP

| Line 1: | Line 1: | ||

| + | === Overview === | ||

| + | This configuration allows the regeneration of one of the analytical columns while the other one is engaged - giving greater efficiency and higher throughput. This is run directly from within '''Analyst® Software'''[https://products.appliedbiosystems.com/ab/en/US/adirect/ab?cmd=catNavigate2&catID=600927&tab=DetailInfo] from ''Applied Biosystems Inc® '' using a LEAP Cycle (requires ICC-CE software) [http://www.leaptec.com/products/lc-related-instruments-and-accessories/ctc-lc-pal-software/instrument-control-components-and-cycle-editor-181.php]. | ||

| + | |||

| + | There are 2 pumps needed, one for the gradient run and another (higher flow rate and isocratic) for regeneration. This configuration requires a 6 port valve[http://www.leaptec.com/products/lc-related-instruments-and-accessories/ctc-lc-pal-injection-valves/6-port-2-position-valve-155.php] for sample loading and a 10 port valve [http://www.leaptec.com/products/lc-related-instruments-and-accessories/ctc-lc-pal-injection-valves/10-port-2-position-valve-157.php]for column switching. All valves must be controlled by the LEAP cycle. | ||

| + | |||

| + | ''Please note: LEAP can not control the MS Selector valve as part of the cycle.'' | ||

| + | |||

There are four Analyst cycles that will be slight variations of the standard LC injection cycle. | There are four Analyst cycles that will be slight variations of the standard LC injection cycle. | ||

Revision as of 02:23, 29 April 2009

Overview

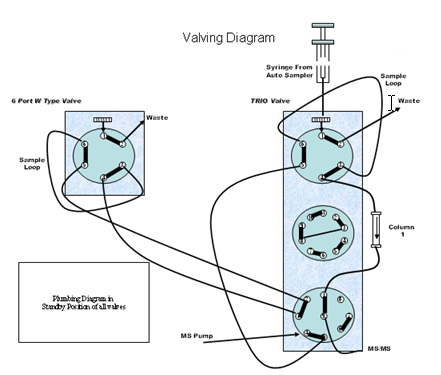

This configuration allows the regeneration of one of the analytical columns while the other one is engaged - giving greater efficiency and higher throughput. This is run directly from within Analyst® Software[1] from Applied Biosystems Inc® using a LEAP Cycle (requires ICC-CE software) [2].

There are 2 pumps needed, one for the gradient run and another (higher flow rate and isocratic) for regeneration. This configuration requires a 6 port valve[3] for sample loading and a 10 port valve [4]for column switching. All valves must be controlled by the LEAP cycle.

Please note: LEAP can not control the MS Selector valve as part of the cycle.

There are four Analyst cycles that will be slight variations of the standard LC injection cycle.

The first cycle is known as a Tuning cycle. It collect samples from the VT-54 tray and passes them directly to the Mass Spec through the stand-alone 6-port LC Valve. By directly, it is meant to emphasize that the sample does not pass through any column whatsoever during its passage to the Mass Spec.

The second and third Analyst cycles inject the sample to the top valve of the TrioVS. The difference between the two cycles is that one passes the sample through column A (connected to ports 10 and 7 of the 2nd Valve of the TrioVS) on its way to the Mass Spec, while the other cycle passes the sample through column B (connected to ports 2 and 5 of the 2nd Valve of the TrioVS).

The final Analyst cycle is used for a single-column application. In this scenario, the second valve of the TrioVS is bypassed altogether. The column will be included in the plumbing lines connecting the 6-port valve of the TrioVS to the selector valve of the TrioVS.

Project Ref: H1108

Contact LEAP

For additional information about this technique please contact LEAP Technologies for detailed information