M-005 Dual Channel Parallel Injection - LEAP Shell "(M-Fab)"

From LEAP

| Line 6: | Line 6: | ||

|description = High Throughput LC injections alternating onto two analytical columns. | |description = High Throughput LC injections alternating onto two analytical columns. | ||

}} | }} | ||

| + | [[Image:LEAP Logo.png|frame|www.leaptec.com<br>www.leapwiki.com]] | ||

| + | === Overview === | ||

| + | This configuration provides minimum cycle times by limiting the acquisition time to just the peaks of interest and regenerating the columns during the acquisition. It uses '''LEAP Shell Scheduling Software'''[http://www.leaptec.com/software/leap-shell-3.php] - this application is integrated with'''Analyst® Software'''[https://products.appliedbiosystems.com/ab/en/US/adirect/ab?cmd=catNavigate2&catID=600927&tab=DetailInfo] from ''Applied Biosystems Inc® ''. There is a single sample list and allows multiplexing of 2 separate HPLC system into one Mass Spec. | ||

| + | <br><br> | ||

| - | |||

| - | |||

*LEAP Shell - '''M-Fab''' application integrated with Analyst with supported pumps. | *LEAP Shell - '''M-Fab''' application integrated with Analyst with supported pumps. | ||

Revision as of 23:42, 28 April 2009

| Dual Channel Parallel Injections with LEAP Shell "M-Fab" |

| Application Type | |

| SPECIAL | |

| Application ID | |

| M-005 | |

| Description | |

| High Throughput LC injections alternating onto two analytical columns. |

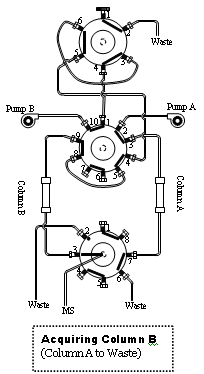

Overview

This configuration provides minimum cycle times by limiting the acquisition time to just the peaks of interest and regenerating the columns during the acquisition. It uses LEAP Shell Scheduling Software[1] - this application is integrated withAnalyst® Software[2] from Applied Biosystems Inc® . There is a single sample list and allows multiplexing of 2 separate HPLC system into one Mass Spec.

- LEAP Shell - M-Fab application integrated with Analyst with supported pumps.

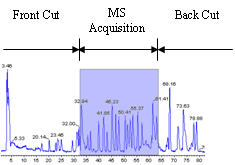

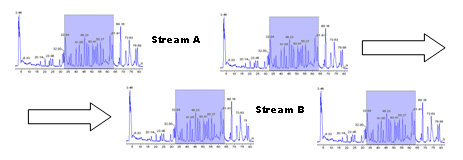

If the peaks of interest come off together in the middle of the gradient (as shown below) then it is possible to utilize the front cut and back cut time to increase throughput.

If injections are staggered in the following way, there is a potential for up to 100% gain:

Hardware Requirements

- TrioVS multiple valve system is required in addition to the standard injection valve.

Contact LEAP

For additional information about this technique please contact LEAP Technologies for detailed information