Certus Liquid Dispenser

From LEAP

| Liquid Dispensing |

| Application Type | |

| Sample Prep | |

| Application ID | |

| Certus Liquid Dispenser | |

| Description | |

| Micro-Nano Liquid dispenser |

Contents |

New step in the technique of high precision dispensing

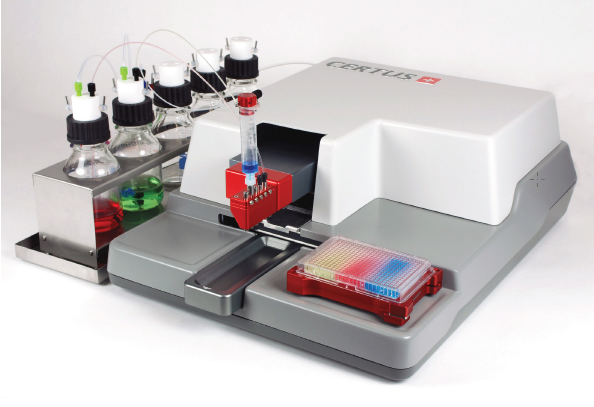

It is with great pride and pleasure, we introduce our new product called “Certus”, a Micro-Nano Liquid dispenser. Certus will meet the demand in world wide of life science and pharmaceutical market, which was launched at LABAutomation 2011 in Palm Springs by Gyger and the US distributor, LEAP Technologies

Overview

- 5-channel dispenser

- Dispensing spectrum 10 nl up to typically 50 μl

- 50 nl precision better than 5% CV

- All standard well plate formats can be filled (96, 384, 1536, 3456)

- Well plate with evaporation barrier can be filled

- Dispensing cells and beads has been done

- Modern intuitive software

- Select multiple well regions: fill as gradient

- Flexible overall concept

- Fast filling

- Small transfer volume

- Contactless dispensing

Certus Dispenser

The dispenser can fill contactless volumes of 10 nl up to typically 50 μl in all well plate formats. Applications can be found mostly in the pharmaceutical research and biotechnology areas, where compound libraries are being screened (HTS). Small volumes of reagents, cells or even beads can be dispensed reliably. The flexibility that the Certus Liquid Dispenser offers will match other complex dispensing tasks in research and production support labs.

Dispensing

- Water

- Alcohols

- DMSO

- Buffers

- Cells

- Beads

- Reagents

- Serum

Great Integration Possibilities

The Certus Liquid Dispenser can be used stand-alone or integrated into a laboratory automation system in high-throughput drug screening (HTS). The Plug In interface provides flexible integration opportunities. Via this interface, operating data can be exported to a company’s own database.

The small size of the dispenser provides space-saving installation.

Dispenser Principle

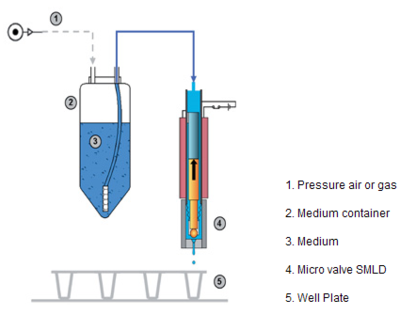

With the applied dispensing principle the medium containers are pressurized by air or gas. This system pressure delivers after the micro valve opens the medium contactless into the requested well or vial.

Functional Possibilities

The 5 channel dispenser controls each micro valve SMLD independently and fills all formats of well plates. The precise xyz-axes are powered with servo motors. There is the same pressure on all medium containers, automatically and infinitely adjustable between 0 – 1 bar. The media containers are located next to the device. Two syringes can be used as medium containers and be mounted directly over the micro valves.

This is critical when extremely expensive media are used. There are filters at the valve inlet and intake tubing of the medium container. Upon request the filters can be removed.

Flexible Certus Liquid Dispenser Software

The Certus Liquid Dispenser software supports the end-user in an intuitive way. All software development is performed according to the newest Microsoft standards. Complex layouts can be created with ease. A micro-well plate can be programmed by different regions. In each region it is possible to select different mediums and filling algorithms. Each medium will be given a different color for an optical differentiation. It does not matter whether work is done with standard well plates or it is a self-created well plate. In addition well plate layouts can be imported through the Excel interface.

Photos

Videos of the PAL

![]() Certus Liquid Dispenser in action on YouTube

Certus Liquid Dispenser in action on YouTube

LEAP Technologies provides fully automated sample processing workstation instrumentation solutions based on the LEAP CTC PAL X, Y, Z syringe only autosampler robot. This extremely flexible, precise, and adaptable liquid handling robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your UHPLC, LC or GC chromatography. LEAP also offers process control systems and stand alone workstations. LEAP is an open, neutral resource for technical support of existing PAL. Keep your PAL in peak working order LEAP offers full support and service for the PAL platform with over 11 years of history with the PAL. LEAP can also write custom macros, cycles, and scheduling software for your specific applications. We're proud that LEAP is known as a productivity improver for laboratories including government labs in agencies such as FDA, USDA, EPA, FBI, Armed Forces, Homeland Security and others function more efficiently. Robotic sample prep equipment works well in government labs and challenges lab technicians to keep feeding those more samples. Analytical equipment such as chromatographs and mass spectrometers are expensive devices and also expensive to maintain. LEAP can help to keep them running and analyze samples around the clock. LEAP has most of its laboratory automation robots under GSAcontract and is eager to service and maintain everything it sells to keep your expensive lab equipment running around the clock. CTC Analytics Combi PAL and HTS PAL for Front-End Automation for LC and GC applications. LEAP offers customized on-site training. LEAP Is continuing to develop FAQ, Solutions, Tips & Techniques,a Learning Center with the LEAP Wiki for the benefit of all PAL Platform Robotic users. We will continue exceeding customer expectations for quality, cost effective and efficient results using the most current technology and expertise in our industry. Our aim is to be the ultimate knowledge base on everything related to the PAL. LEAP is known as the autosamplerguys being in business over twenty years. LEAP has extensive multi-vendor experience with integrating the PAL. HTX, HTS, HTC, HTX-xt, HTS-xt, HTC-xt, LC-Mini, Combi PAL,COMBI-xt PAL, and GC PAL models. We have the Quality, Training, Parts availability, Infrastructure, and Experience.LEAP is sometimes referred to as an Application Automation House who is continually adding new products and solutions to its Lab Automation line. As we do so we change the content of this web site so please check back.

Please contact LEAP Technologies on how we can help you get maximized throughput with flexible pipetting automation solutions whether it is our standard applications or customized to your needs. The Combi-xt PAL autosampler is able to perform liquid and headspace analysis. Headspace options include Solid Phase Micro-extraction (SPME) and ITEX-2 as alternative to purge and trap. The HTS-xt PAL autosampler dramatically increases sample throughput by offering automated sample prep, Peltier cooled and heated sample storage using the cooled stack, Peltier cooled and heated sample storage using the cooled stack and low carryover due to the self-cleaning DLW (Dynamic Load and Wash) module and L-Mark syringes, peltier cooled valves and columns. LEAP provides automation that fits your needs and reduces errors, increases sample capacity, increases efficiency, reduces cost by supplying long term productivity improvements with user friendly software and flexible hardware. LEAP performs just in time or on time sample prep and inject. LEAP offers full support of integrated and non-integrated PAL software with both sales and support for Cruise Control, Cycle Composer and Cycle Composer Macro Editor, Agilent ChemStation CTC Control, Mass Hunter and EZChrom CTC integration, Xcalibur, Waters Masslynx or Analyst CTC Control software, Thermo (Finnegan) XCalibur, LEAP Shell, and Chronos software. The PAL is more than just an autosampler, it is a high-quality and efficient laboratory robot platform that can be customized by LEAP Technologies to meet your specific needs. Fritz Gyger AG specializes in the development and manufacturing of precision engineered components and functional modules extending to complete micro-mechanical systems and often make use of high-tech materials, such as engineering ceramics and titanium. Key areas of our expertise are precision fluid handling devices, with a focus on micro solenoid valves and pumping systems for HPLC analysis. LEAP is happy to be the US distributor for the Certus Dispenser.

Contact LEAP

For additional information about LEAP and the Geyger Liquid Dispenser including a brochure, please contact LEAP Technologies. |

The information and references contained in this web site are believed to be accurate and the most current information available.

Keywords: LEAP Technologies Dispenser Principle With the applied dispensing principle the medium containers are pressurized by air or gas. This system pressure delivers after the micro valve opens the medium contactless into the requested well or vial. 1. Pressure air or gas 2. Medium container 3. Medium 4. Micro valve SMLD 5. Well Plate FUNCTIONAL POSSIBILITIES The 5 channel dispenser controls each micro valve SMLD independently and fills all formats of well plates. The precise xyz-axes are powered with servo motors. There is the same pressure on all medium containers, automatically and infinitely adjustable between 0 – 1 bar. The media containers are located next to the device. Two syringes can be used as medium containers and be mounted directly over the micro valves. This is critical when extremely expensive media are used. There are filters at the valve inlet and intake tubing of the medium container. Upon request the filters can be removed. GOOD INTEGRATION POSSIBILITIES The Certus Liquid Dispenser can be used stand-alone or integrated into a laboratory automation system in high-throughput drug screening (HTS). The Plug In interface provides flexible integration opportunities. Via this interface, operating data can be exported to a company’s own database. The small size of the dispenser provides space-saving installation.FLEXIBLE CERTUS LIQUID DISPENSER SOFTWARE The Certus Liquid Dispenser software supports the end-user in an intuitive way. All software development is performed according to the newest Microsoft standards. Complex layouts can be created with ease. A micro-well plate can be programmed by different regions. In each region it is possible to select different mediums and filling algorithms. Each medium will be given a different colour color for an optical differentiation. It does not matter whether work is done with standard well plates or it is a self-created well plate. In addition well plate layouts can be imported through the Excel interface. 1. New and saved experiments 2. Select existing views 3. Maintenance and properties functions 4. Overview of available media 5. Quick access to existing experiments 6. Scroll through the views 7. Well plate regions 8. Region editor Well Plate Formats Well plate formats standard SBS 3456, 1536, 384, 96 and Deep Well Plate versions Well plate with evaporation barrier 384 Aurora, 1536 Novartis Additional functions User designed plates Well Plate height 0 -50 mm Capacity (number of well plates) 1 Orientation of well plates Side ways Dispensing speed P = 0.3 bar, 1 micro valve SMLD 300G, Dispensing volume 50 nl and 500 nl 96 Well Plate: dispensing time 19 sec 384 Well Plate: dispensing time 47 sec 1536 Well Plate: dispensing time 145 sec Dispensing Head Channel numbers 5 with 5 different media Dispensing principle contactless, drop-on-demand Dispensing volume, dynamic range ≥ 10 nl Inner volume 65 μl SMLD 300G Precision, CV 50 nl ≤ CV 5% 500 nl ≤ CV 3% Accuracy 500 nl ± 3% Media Management Media container 5 external containers or 3 external containers and 2 syringes connected to micro valve Type of media 100% DMSO to serum based Pressure range 0 -1 bar Waste container 1 with drain Filter Built-in filter on micro valve SMLD Pre-filter for media container at the intake tubing Without filter on request General Testing and adjustments Each channel separately Flushing, filling and draining Each channel separately automatically Handling PC based software Hardware-Interface Ethernet Software-Interface Plug In interface Pneumatics 1.7 - 2 bar inlet pressure Power 110 - 240 V 50/60 Hz nominal Dimensions (L x W x H) 555 x 425 x 180 mm Weight 17 kg