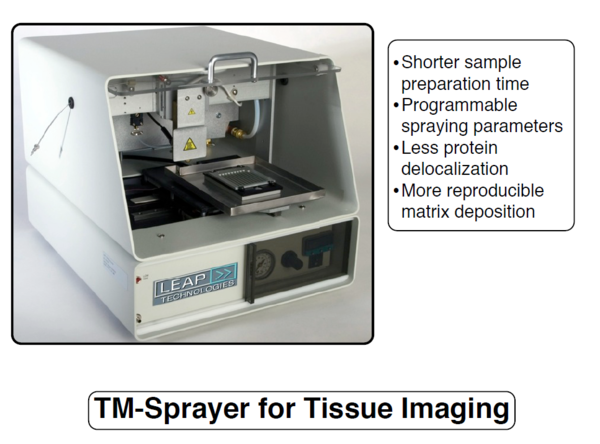

Tm-Sprayer

From LEAP

| Agitation of Samples |

| Application Type | |

| Proteomics | |

| Application ID | |

| Description | |

Sample preparation automation to produce consistent and superior reliably coated tissue sections for MALDI Imaging MS TM-Sprayer delivers coating of Matrix, Reagents

TM-Sprayer for Matrix Tissue MALDI:

- Patented nozzle/air sprayer system

- Stage for 1-2 MALDI plates

- PC with instrument software

- Isocratic pump with solvent bottles

- Installation and end-user training included

Description

Automatic and Consistent Matrix Spraying

- Easy to use, off-line system works for all MALDI target plates

- Meandering spray pattern

- Track width from 1mm to 20mm

- Uniform and consistent coating crucial for reliable imaging spectral data

- Great versatility is offered for multiple matrices

- Field proven reliability

- Matrix spray coating is achieved as solvent is removed by evaporation

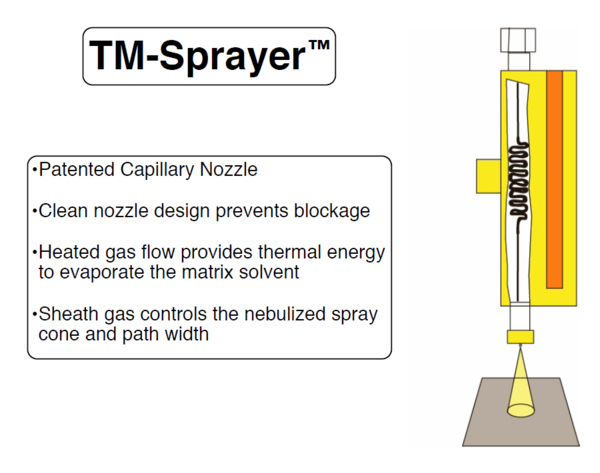

- Flows through a heated, patented nozzle, permits processing up to 1.0ml/min of volatile solvents and 0.2ml/min of aqueous solutions

- Programmable robotic 2-axis stage under fixed nozzle

- Nozzle height above target, temperature of matrix/solvent mix, temperature of gas and forward speed of cross table can be controlled to equal proper application wetness

TM-Sprayer™ is an easy-to-use, versatile spraying system that provides an automated process for the preparation of MALDI plates. The patented technology1 of the TMSprayer ™ guarantees a very uniform and consistent coating crucial for reliable imaging.

The unique design of the TM-Sprayer™ spray nozzle creates a fine solvent mist that is transported by a heated inert gas and quickly evaporates upon contact with the MALDI plates. Spray characteristics are easily adjustable via our intuitive Operator Interface. Users can select from a large selection of spray pattern designs and plate types to meet the requirements of their application.

Techniques for spray coating have utilized manual methods of matrix deposition, and are subject to variations dependent on the individual preparing the sample. Standardization of the matrix deposition provides a uniform and reproducible methodology. In the TM-Sprayer, a constant flow of heated sheath gas is delivered conjointly with the matrix spray which results in two major benefits:

- Very rapid evaporation for minimal analyte delocalization.

- Highly efficient co-crystallization for superior mass spec signal.

Coupled with the benefit of faster sample preparation, the TM-Sprayer™ delivers the automated matrix deposition solution required to keep up with the high speed of the latest MALDI Mass Spectrometers.

Large choice of Matrix.

The design of the matrix flow path provides a great flexibility in solvent choices. The TM-Sprayer™ permits processing of up to

1.0ml/min of matrix solution. Flow rates are controlled through an auxiliary pump.

Consistent Matrix Spraying

The temperature control technology used for the patented nozzle of the TM-Sprayer™ ensures very stable and reproducible spray characteristics, across a wide range of matrix solvent.

Adjustable Method Parameters Nozzle height above target, temperature of matrix/solvent mix, temperature of gas andforward speed of cross table are easily controlled to result in proper application wetness, optimal resolution and extraction performance.

High Quality Robotics The precise robotics of the TM-Sprayer™ deliver a smooth and constant-speed linear displacement of the MALDI target along the X-Y axis, which results in a uniform matrix deposition. Hot-spots often associated with manual techniques are eliminated.

Easy Method Development The TM-Sprayer can save an unlimited number of methods, which makes it easy to access optimal parameters for each sample type of MALDI plate, matrix chemistry or types of tissue samples.

Intuitive User Interface

- Microsoft Windows™ Operator Interface

- Single view User Interface

- Graphical Selection of the desired deposition areas

- Linear offset tracks or an alternating 90° rotation during matrix application

- Save and Load routine sample programs

Large selection of Spray Pattern Design Select from serpentine to vertical or horizontal line patterns.

Custom configurable MALDI plate interface and multi-vendor plate holder Create new plate types using the simple plate configuration tool.

TM-Sprayer™ Specifications

- Deposition – Spray deposition in linear or serpentine modes with variables offsets. Spray patterns by alternating perpendicular paths for even coatings.

- Nozzle Flow – 50 to 1000μl/min

- Sheath Gas – Ambient to 200°C (+/- 2°C),software selected

- Collection Unit – X-Y Robotic Stage,fixed nozzle

- Gas Supply Sheath gas flow 5-15.5 liter/min

- Electrical 120 VAC, 60 Hz or 220 VAC, 50Hz: 2.5A fused

- Dimensions/Weight 42x34x31 cm, 14kg

Minimal Maintenance and Easy Service All key components are easily accessible for quick adjustment or maintenance.

Photos

TM-Sprayer™ is available worldwide from LEAP Technologies, Inc.

LEAP strives to find total solutions for analytical lab automation by automating analytical processes for small and large molecules in extracted liquids, solids, and recently in human, animal and plant tissues. We provide the precise robotics and efficient sample prep required by modern measurement techniques such as MALDITOF mass spectroscopy. Our newest specialty customization of CTC Analytics’ PAL features small workstations that can perform complex liquid handling tasks including HPLC-Purification, SPE, filtration, weighing, heating and stirring. They can be configured as stand alone units or integrated for “just in time” sample prep for LC-MS or GC-MS analysis.

LEAP provides automated workstation instrumentation solutions based on the LEAP CTC PAL X, Y, Z syringe only autosampler robot from LEAP Technologies. This extremely flexible, precise, and adaptable liquid handling robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your UHPLC, LC or GC chromatography.LEAP offers full support and service for the PAL platform in addition to being able to write custom macros, cycles, and scheduling to your applications. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible pipetting automation solutions.

Contact LEAP

For additional information about LEAP and the PAL Platform, please contact LEAP Technologies. |