Semi Solid Applications

From LEAP

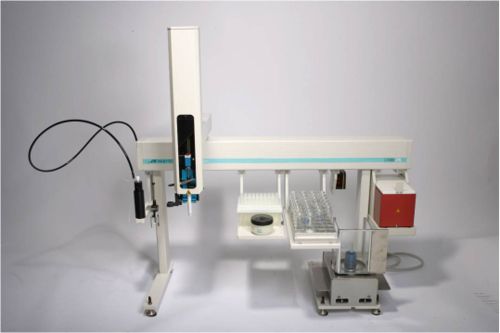

| Semi-Solid Workstation |

| Application Type | |

| SPECIAL | |

| Application ID | |

| Semi-Solid Workstation PAL | |

| Description | |

| Semi-Solid Sample Preparation Workstation |

Contents |

General Description

Conventional pipettes and syringes are not suited to handling high density samples such as creams and emulsions. The sample will be tend to adhere to the tip resulting in poor precision and accuracy.

The Semi-Solid Workstation is designed to automate the weighing of semisolid samples, having the qualities of both a solid and a liquid, in 20ml or 10ml uncapped vials. Semi-solid samples can be a cream and highly viscous consistency and may represent toothpaste, lotion, ointment, oil, perfumes,essence, cosmetic, paste, emulsion oils, salve, liniment, fuels, unguent, lubricant,radioactive materials, drug products and baby food. The LEAP has adapted the Ranin's Pos-D™ technology for use on the PAL autosampler and also works well for applications requiring the pipetting of viscous, volatile, dense, or high surface- tension liquids or contaminated liquids and hazardous or radioactive compounds. It can even eliminate cross contamination in PCR, forensics and diagnostics.

Significant Markets

- Pharmaceutical

- Petrochemical

- Cosmetics

- Molecular biology

- Forensic science

- PCR studies

- Environmental

- Food and beverage

- Biotech

- Diagnostics

- Industrial laboratories

What is an Semi-Solid experiment ?

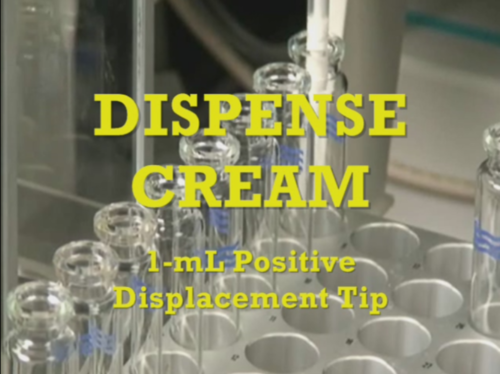

Performing dispensing of semi-solid liquids manually involves the tedious task of pipetting a cream or similar viscous material into tared vials and then reweighing them to determine the exact weight afterward. From this step the process can do various sample prep steps including dilutions and filtration either online or on a separate workstation. LEAP strives to over come the challenges and characterizations of semi-solids morphology, composition and spatial distribution.

Overview of Semi-Solid PAL System

Semi-Solid Workstation is an easy-to-use, system that provides an automated process for the scheduling and repetitive execution of weighing and dispensing workflow. By use of the advanced LEAP Shell scheduling software experimental design is simplified and reliable.

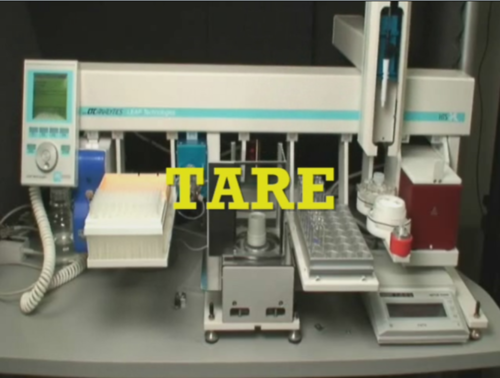

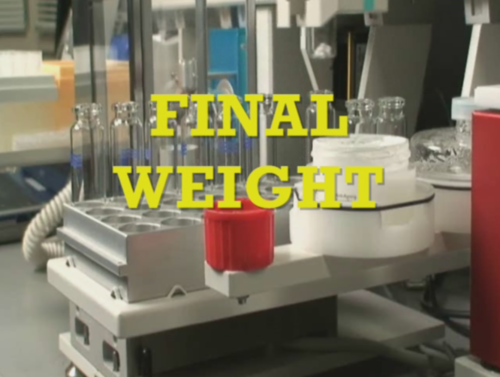

The application will tare vials, then the system will add a semi solid 'cream' to each vial with individual disposable tips. Once the samples in the sample list are dispensed each vial is re-weighed and calculation and report of the net sample weight. A barcode scanner is included in the setup, and scanning is an option in the method. Values for sample ID, barcode, tare weight and sample weight are recorded in a text file. Barcode validation is optional if the codes do not match from the tare step to the weigh step, the sample is flagged in the output file. It is designed so that the output file can be imported into the sample list of another PAL workstation which will use the sample ID and weight information to do an automatic proportional dilution and filtration step.

What does the Semi-Solid PAL do?

The vial is transported using a mechanical gripper which will accommodate 10 or 20 mL vials which are uncapped, screw-capped or crimp-capped

Positive displacement disposable tips are used to dispense the semi-solid liquid (cream)into uncapped vials

A barcode scanner is included in the setup, and scanning is an option in the method

The balance PAL provides the integration of a robotic accessible balance with the x,y,z, robot platform

Sample Process of the Semi-Solid PAL

- Tare empty vials

- Dispense semi-solid to each vial with individual disposable tips

- Each vial is re-weighed and calculation and report of the net sample weight is created

- Values for sample ID, barcode, tare weight and sample weight are recorded in a text file

- Barcode validation is optional if the codes do not match from the tare step to the weigh step, the sample is flagged in the output file

- Output file can be imported into the sample list of another PAL workstation which will use the sample ID and weight information to do an automatic proportional dilution and filtration step

The Pos-D™ is especially suited for liquids with high densities, viscosities or vapor pressures. Given the disposable capillaries and pistons, positive displacement absolutely eliminates cross-contamination from aerosols, samples or pipette.

Very viscous, high surface-tension or high density liquids such as 50% glycerol solutions, detergents, oil, syrup or even can be easily pipetted with accuracy and precision

Provides ease, speed, accuracy, precision & safety of these difficult samples

Use of a Positive Displacement Pipette overcomes many of the challenges of semi-solid samples

- Zero Carryover

- High accuracy and precision of difficult liquids

The PAL has been adapted to hold this removable tip assembly in place of a syringe

Quality control of such samples as creams perfumes, emulsions and lotions require repeated sample prep steps that are well suited for the LEAP Semi-Solid PAL

For assurance of good repeatability, sample volumes can be confirmed gravimetrically.[1]

Software Control

LEAP has developed a scheduling application using their proprietary software “LEAP Shell” which will automate the above steps.

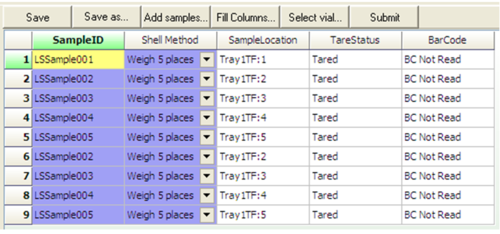

LEAP Shell Screen Shot 2: LEAP Shell Sample List display:

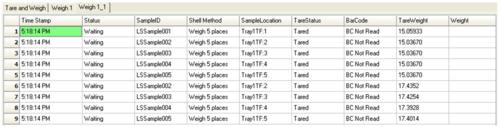

LEAP Shell Screen Shot 3: LEAP Shell Sample Batch display:

Detailed information on RANIN's Pos-D™ technology

Positive Displacement pipettes

Pos-D™ has a disposable piston, which moves within a plastic capillary, makes direct contact with the liquid. The positive wiping action of the piston against the capillary wall assures complete dispensing without droplets.

Both Piston and capillary are disposable and come as a unit

The PAL has been adapted to hold this removable tip assembly in place of a syringe.

Videos of the PAL

![]() Semi Solid Weighing station in action on YouTube

Semi Solid Weighing station in action on YouTube

Hit back button when done to return

![]() Various PAL's in action on YouTube

Various PAL's in action on YouTube

Download

![]() PDF of this page formatted for printing

PDF of this page formatted for printing

![]() RAININ article on Testing of Creams and Emulsions for positive Displacement Pipetting

RAININ article on Testing of Creams and Emulsions for positive Displacement Pipetting

![]() RAININ article on Pipetting of Non-Aqueous Fluids – With Positive Displacement Pipettes

RAININ article on Pipetting of Non-Aqueous Fluids – With Positive Displacement Pipettes

Accessories for the PAL

![]() Other Accessories for PAL Robots

Other Accessories for PAL Robots

![]() Bar Code Reading

Bar Code Reading

![]() Balance PAL

Balance PAL

LEAP has proven capability to solve complex automation challenges in areas which have previously been out of reach.

LEAP provides automated workstation instrumentation solutions based on the LEAP CTC PAL X, Y, Z syringe only autosampler robot from LEAP Technologies. This extremely flexible, precise, and adaptable liquid handling robotic platform is available in a variety of lengths and options depending on the requirements of your sample preparation and injections for your UHPLC, LC or GC chromatography.LEAP offers full support and service for the PAL platform in addition to being able to write custom macros, cycles, and scheduling to your applications. Please contact LEAP Technologies on how we can help you get maximized throughput with flexible pipetting automation solutions.

Contact LEAP

For additional information about LEAP and the PAL Platform, please contact LEAP Technologies. |